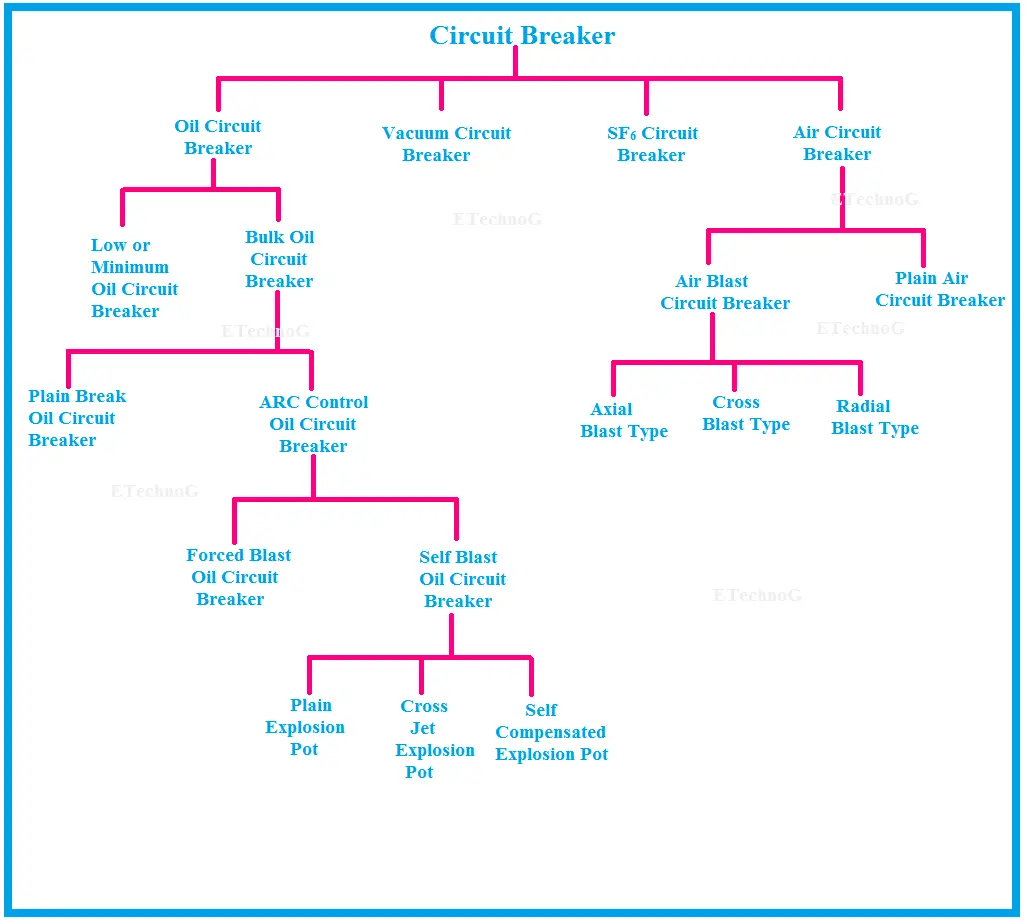

As discussed in the previous articles (Oil Circuit Breakers: Types, Advantages, Disadvantages & Maintainance), the oil circuit breakers can be classified into the following two types: (i) Bulk oil circuit breakers and (ii) Low oil circuit breakers

(i) Bulk oil circuit breakers:- Which use a large quantity of oil. The oil has to serve two purposes. Firstly, it extinguishes the arc during the opening of contacts and secondly, it insulates the current-conducting parts from one another and from the earthed tank. Such circuit breakers may be classified into:-

- (a) Plain break oil circuit breakers, and

- (b) Arc control oil circuit breakers.

(ii) Low oil circuit breakers:- which use the minimum amount of oil. In such circuit breakers, oil is used only for arc extinction; the current-conducting parts are insulated by air or porcelain, or organic insulating material.

In this article, we will explain only Arc control oil circuit breakers… let’s dive in…

- Also, see: Arc Phenomenon | Principle of Arc Extinction | Method of Arc Extinction in Circuit Breaker

- Oil Circuit Breakers: Types, Advantages, Disadvantages & Maintainance

-

Vacuum Circuit Breaker: Construction, Working & Applications

Explanation of Arc Control Oil Circuit Breakers

In the case of the plain-break oil circuit breaker discussed above, there is very little artificial control over the arc. Therefore, a comparatively long arc length is essential in order that turbulence in the oil caused by the gas may assist in quenching it. However, it is necessary and desirable that final arc extinction should occur while the contact gap is still short. For this purpose, some arc control is incorporated and the breakers are then called arc control circuit breakers. Arc control CB is one type of buck oil CB. There are two types of such breakers, namely:

- Self-blast oil circuit breakers— in which arc control is provided by internal means i.e. the arc itself is employed for its own extinction efficiently.

- Forced-blast oil circuit breakers— in which arc control is provided by mechanical means external to the circuit breaker.

(i) Self-blast oil circuit breakers.

In this type of circuit breaker, the gases produced during arcing are confined to a small volume by the use of an insulating rigid pressure chamber or pot surrounding the contacts. Since the space available for the arc gases is restricted by the chamber, very high pressure is developed to force the oil and gas through or around the arc to extinguish it. The magnitude of pressure developed depends upon the value of the fault current to be interrupted.

As the pressure is generated by the arc itself, therefore, such breakers are sometimes called self-generated pressure oil circuit breakers. The pressure chamber is relatively cheap to make and gives reduced final arc extinction gap length and arcing time as against the plain-break oil circuit breaker. Several designs of pressure chambers (sometimes called explosion pots) have been developed and a few of them are described below:

-

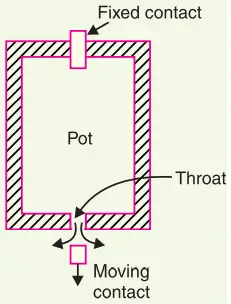

Plain explosion pot.

It is a rigid cylinder of insulating material and encloses the fixed and moving contacts (See Fig. above). The moving contact is a cylindrical rod passing through a restricted opening (called throat) at the bottom. When a fault occurs, the contacts get separated and an arc is struck between them. The heat of the arc decomposes oil into a gas at very high pressure in the pot.

This high pressure forces the oil and gas through and around the arc to extinguish it. If the final arc extinction does not take place while the moving contact is still within the pot, it occurs immediately after the moving contact leaves the pot. It is because the emergence of the moving contact from the pot is followed by a violent rush of gas and oil through the throat producing rapid extinction.

-

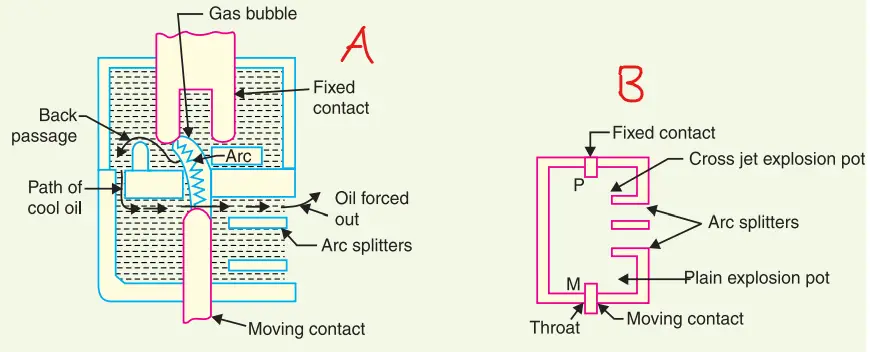

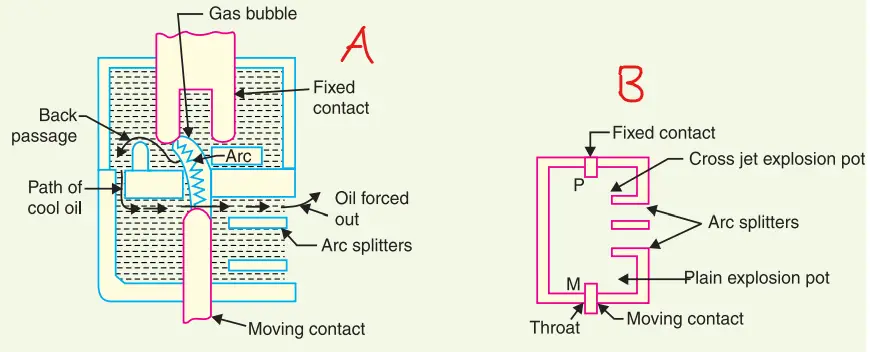

Cross jet explosion pot

This type of pot is just a modification of a plain explosion pot and is illustrated in Fig. A. It is made of insulating material and has channels on one side that act as arc splitters. The arc splitters help in increasing the arc length, thus facilitating arc extinction. When a fault occurs, the moving contact of the circuit breaker begins to separate.

As the moving contact is withdrawn, the arc is initially struck at the top of the pot. The gas generated by the arc exerts pressure on the oil in the back passage. When the moving contact uncovers the arc splitter ducts, fresh oil is forced *across the arc path. The arc is, therefore, driven sideways into the “arc splitters” which increase the arc length, causing arc extinction.

-

Self-compensated explosion pot.

This type of pot is essentially a combination of plain explosion pot and cross jet explosion pot. Therefore, it can interrupt low as well as heavy short circuit currents with reasonable accuracy.

Fig. B shows the schematic diagram of the self-compensated explosion pot. It consists of two chambers; the upper chamber is the cross-jet explosion pot with two arc splitter ducts while the lower one is the plain explosion pot. When the short-circuit current is heavy, the rate of generation of gas is very high and the device behaves as a cross-jet explosion pot. The arc extinction takes place when the moving contact uncovers the first or second arc splitter duct.

Fig. B shows the schematic diagram of the self-compensated explosion pot. It consists of two chambers; the upper chamber is the cross-jet explosion pot with two arc splitter ducts while the lower one is the plain explosion pot. When the short-circuit current is heavy, the rate of generation of gas is very high and the device behaves as a cross-jet explosion pot. The arc extinction takes place when the moving contact uncovers the first or second arc splitter duct.

However, on low short-circuit currents, the rate of gas generation is small and the tip of the moving contact has the time to reach the lower chamber. During this time, the gas builds up sufficient pressure as there is very little leakage through arc splitter ducts due to the obstruction offered by the arc path and right-angle bends. When the moving contact comes out of the throat, the arc is extinguished by plain pot action.

(ii) Forced-blast oil circuit breakers.

In the self-blast oil circuit breakers discussed above, the arc itself generates the necessary pressure to force the oil across the arc path. The major limitation of such breakers is that arcing times tend to be long and inconsistent when operating against currents considerably less than the rated currents. It is because the gas generated is much reduced at low values of fault currents. This difficulty is overcome in forced-blast oil circuit breakers in which the necessary pressure is generated by external mechanical means independent of the fault currents to be broken.

In a forced-blast oil circuit breaker, oil pressure is created by the piston-cylinder arrangement. The movement of the piston is mechanically coupled to the moving contact. When a fault occurs, the contacts get separated by the protective system, and an arc is struck between the contacts. The piston forces a jet of oil towards the contact gap to extinguish the arc. It may be noted that the necessary oil pressure produced does not in any way depend upon the fault current to be broken.

Reference Book: Principles of power systems vk-mehta