In the bulk oil circuit breakers discussed earlier, the oil has to perform two functions. Firstly, it acts as an arc quenching medium and secondly, it insulates the live parts from the earth. It has been found that only a small percentage of oil is actually used for arc extinction while the major part is utilized for insulation purposes. For this reason, the quantity of oil in bulk oil circuit breakers reaches a very high figure as the system voltage increases. This not only increases the expenses, tank size, and weight of the breaker but also increases the fire risk and maintenance problems.

The fact that only a small percentage of oil (about 10% of the total) in the bulk oil circuit breaker is actually used for arc extinction leads to the question as to why the remainder of the oil, that is not immediately surrounding the device, should not be omitted with consequent saving in bulk, weight, and fire risk. This led to the development of a low-oil circuit breaker.

A low oil circuit breaker employs solid materials for insulation purposes and uses a small quantity of oil which is just sufficient for arc extinction. As regards quenching the arc, the oil behaves identically in bulk as well as a low oil circuit breaker. By using suitable arc control devices, the arc extinction can be further facilitated in a low oil circuit breaker.

Construction

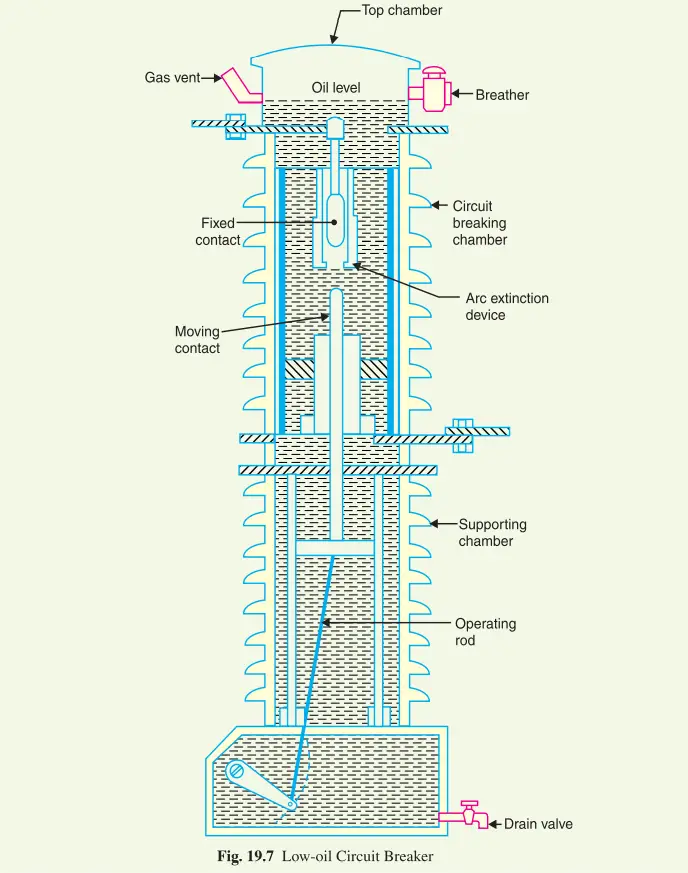

The figure above shows the cross-section of a single-phase low oil circuit breaker. There are two compartments separated from each other but both filled with oil. The upper chamber is the circuit breaking chamber while the lower one is the supporting chamber. The two chambers are separated by a partition and oil from one chamber is prevented from mixing with the other chamber. This arrangement permits two advantages. Firstly, the circuit breaking chamber requires a small volume of oil which is just enough for arc extinction. Secondly, the amount of oil to be replaced is reduced as the oil in the supporting chamber does not get contaminated by the arc.

(i) Supporting chamber

It is a porcelain chamber mounted on a metal chamber. It is filled with oil which is physically separated from the oil in the circuit breaking compartment. The oil inside the supporting chamber and the annular space formed between the porcelain insula[1]tion and bakelite paper are employed for insulation purposes only.

(ii) Circuit-breaking chamber

It is a porcelain enclosure mounted on the top of the supporting compartment. It is filled with oil and has the following parts: (a) upper and lower fixed contacts (b) moving contact (c) turbulator

The moving contact is hollow and includes a cylinder that moves down over a fixed piston. The turbulator is an arc control device and has both axial and radial vents. Axial venting ensures the interruption of low currents whereas radial venting helps in the interruption of heavy currents.

(iii) Top chamber

It is a metal chamber and is mounted on the circuit-breaking chamber. It provides expansion space for the oil in the circuit-breaking compartment. The top chamber is also provided with a separator which prevents any loss of oil by centrifugal action caused by circuit breaker operation during fault conditions.

Operation

Under normal operating conditions, the moving contact remains engaged with the upper fixed contact. When a fault occurs, the moving contact is pulled down by the tripping springs and an arc is struck. The arc energy vaporizes the oil and produces gases under high pressure. This action constrains the oil to pass through a central hole in the moving contact and results in forcing a series of oil through the respective passages of the turbulator. The process of tribulation is orderly, in which the sections of the arc are successively quenched by the effect of separate streams of oil moving across each section in turn and bearing away its gases.

Advantages

A low oil circuit breaker has the following advantages over a bulk oil circuit breaker:

- It requires a lesser quantity of oil.

- It requires smaller space.

- There is a reduced risk of fire.

- Maintenance problems are reduced.

Disadvantages

A low oil circuit breaker has the following disadvantages as compared to a bulk oil circuit breaker:

- Due to the smaller quantity of oil, the degree of carbonization is increased.

- There is a difficulty in removing the gases from the contact space in time.

- The dielectric strength of the oil deteriorates rapidly due to a high degree of carbonization.

Reference Book: Principles of power systems vk-mehta