Earlier we have discussed the following topics given below, check it if you are still not yet read:

Lets dive in to our main topic:

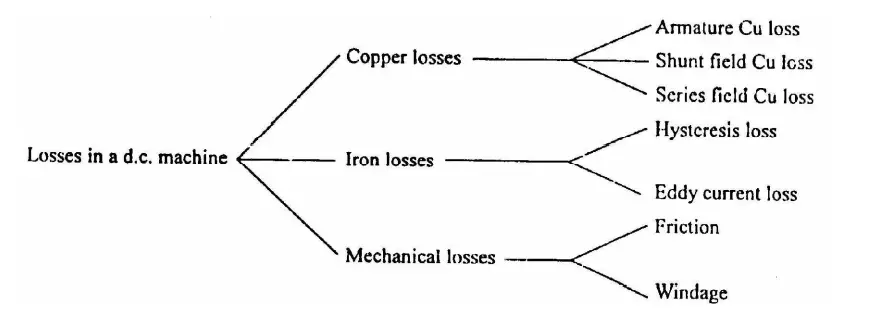

The losses in a d.c. machine (generator or motor) may be divided into three classes viz (i)Copper losses (ii) Iron or core losses and (iii) Mechanical losses. All these losses appear as heat and thus raise the temperature of the machine. They also lower the efficiency of the machine.

1. Copper losses

These losses occur due to currents in the various windings of the machine.

- Armature copper loss = Ia2Ra

- Shunt field copper loss = Ish2Rsh

- Series field copper loss = Ise2Rse

Note: There is also brush contact loss due to brush contact resistance (i.e., the resistance between the surface of the brush and the surface of the commutator). This loss is generally included in armature copper loss.

2. Iron or Core losses

These losses occur in the armature of a d.c. machine and are due to the rotation of armature in the magnetic field of the poles. They are of two types viz., (i) hysteresis loss and (ii) eddy current loss.

(i) Hysteresis loss

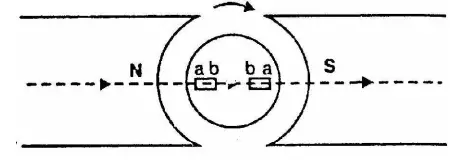

Hysteresis loss occurs in the armature of the d.c. machine since any given part of the armature is subjected to magnetic field reversals as it passes under successive poles. The figure above shows an armature rotating in a two-pole machine.

Hysteresis loss occurs in the armature of the d.c. machine since any given part of the armature is subjected to magnetic field reversals as it passes under successive poles. The figure above shows an armature rotating in a two-pole machine.

Consider a small piece ab of the armature. When the piece ab is under N-pole, the magnetic lines pass from a to b. Half a revolution later, the same piece of iron is under S-pole and magnetic lines pass from b to a so that magnetism in the iron is reversed. In order to reverse continuously the molecular magnets in the armature core, some amount of power has to be spent which is called hysteresis loss. It is given by the Steinmetz formula. This formula is-![]()

where Bmax= Maximum flux density in the armature

f = Frequency of magnetic reversals = NP/120 where N is in r.p.m.

V= Volume of armature in m3

h= Steinmetz hysteresis co-efficient

In order to reduce this loss in a d.c. machine, armature core is made of such materials which have a low value of Steinmetz hysteresis co-efficient e.g., silicon steel.

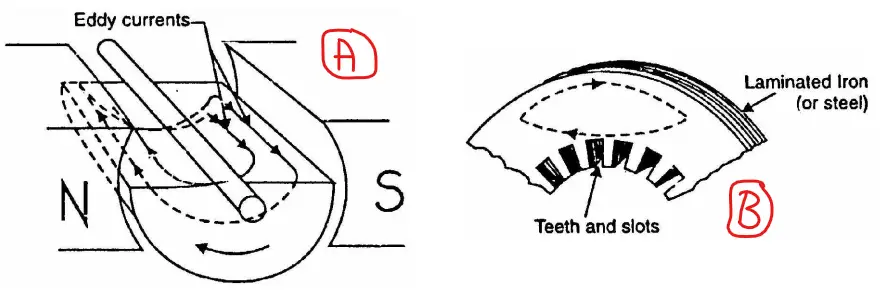

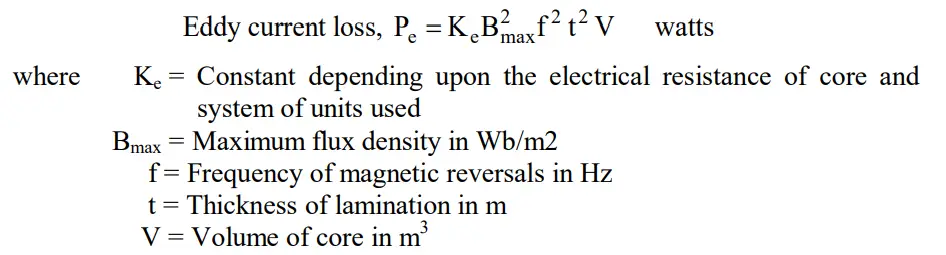

(ii) Eddy’s current loss

In addition to the voltages induced in the armature conductors, there are also voltages induced in the armature core. These voltages produce circulating currents in the armature core as shown in Fig. A. These are called eddy currents and power loss due to their flow is called eddy current loss. The eddy current loss appears as heat which raises the temperature of the machine and lowers its efficiency. If a continuous solid iron core is used, the resistance to the eddy current path will be small due to the large cross-sectional area of the core. Consequently, the magnitude of eddy current and hence eddy current loss will be large. The magnitude of eddy current can be reduced by making core resistance as high as practical. The core resistance can be greatly increased by constructing the core of thin, round iron sheets called laminations [See Fig. B].

If a continuous solid iron core is used, the resistance to the eddy current path will be small due to the large cross-sectional area of the core. Consequently, the magnitude of eddy current and hence eddy current loss will be large. The magnitude of eddy current can be reduced by making core resistance as high as practical. The core resistance can be greatly increased by constructing the core of thin, round iron sheets called laminations [See Fig. B].

The laminations are insulated from each other with a coating of varnish. The insulating coating has a high resistance, so the very little current flows from one lamination to the other. Also, because each lamination is very thin, the resistance to current flowing through the width of lamination is also quite large. Thus laminating a core increases the core resistance which decreases the eddy current and hence the eddy current loss.

It may be noted that eddy current loss depends upon the square of lamination thickness. For this reason, lamination thickness should be kept as small as possible.

3. Mechanical losses

These losses are due to friction and windage.

- Friction loss e.g., bearing friction, brush friction, etc.

- Windage loss i.e., air friction of rotating armature.

These losses depend upon the speed of the machine. But for a given speed, they

are practically constant.

[Note: Iron losses and mechanical losses together are called stray losses.]

Constant and Variable Losses

The losses in a d.c. generator (or d.c. motor) may be sub-divided into (i)

constant losses (ii) variable losses.

(i) Constant losses

Those losses in a d.c. generator which remains constant at all loads are known as

constant losses. The constant losses in a d.c. generator are:

(a) iron losses

(b) mechanical losses

(c) shunt field losses

(ii) Variable losses

Those losses in a d.c. generator which varies with load is called variable losses.

The variable losses in a d.c. generator are:

[Note: Field Cu loss is constant for shunt and compound generators]

References: Principles of Electrical Machine by V.K MEHTA